Timing belt conveyors

Timing belt conveyors are suitable for inter-operation transport of piece products, pallets, with the requirement of serial repeatability. The components used are of robust construction, characterized by a long service life and thus allow repeated use. The base of the system consists of an aluminium profile support frame, conveyor belt and guides. The choice of the appropriate type and width of the belt is determined by the final product (according to its shape) as well as the pallet design and maximum load.

Version

- conveyor base frame and base made of ALUTEC KK aluminium construction system

- drive and driven pulley with tooth module AT5, AT10, AT20, if necessary other module can be used

- Aluminium drive and driven pulley holders with tilting ball bearings and simple system for adjustment and tensioning of the conveyor belt, single-row, double-row and multi-row conveyors can be manufactured

- drive consists of a compact unit comprising a three-phase asynchronous electric motor and worm gearbox

- for heavier loads, bevel gearbox

- belts can be ESD coated including ESD plastic support line

- transport of parts may be in accumulation

Optional accessories

- electrical connection of conveyors

- optical sensors with reflector, safety STOP buttons

- frequency converter, motor starter

- base, drive according to your specifications

- plastic slide rails with raised edges

- side guides adjustable in horizontal only or in both horizontal and vertical directions

Special solutions

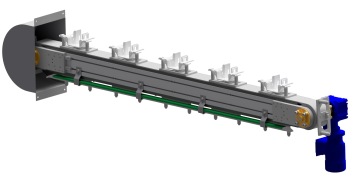

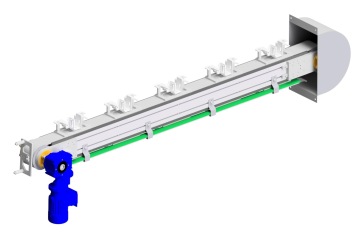

Conveyor without base

to be built into your equipment

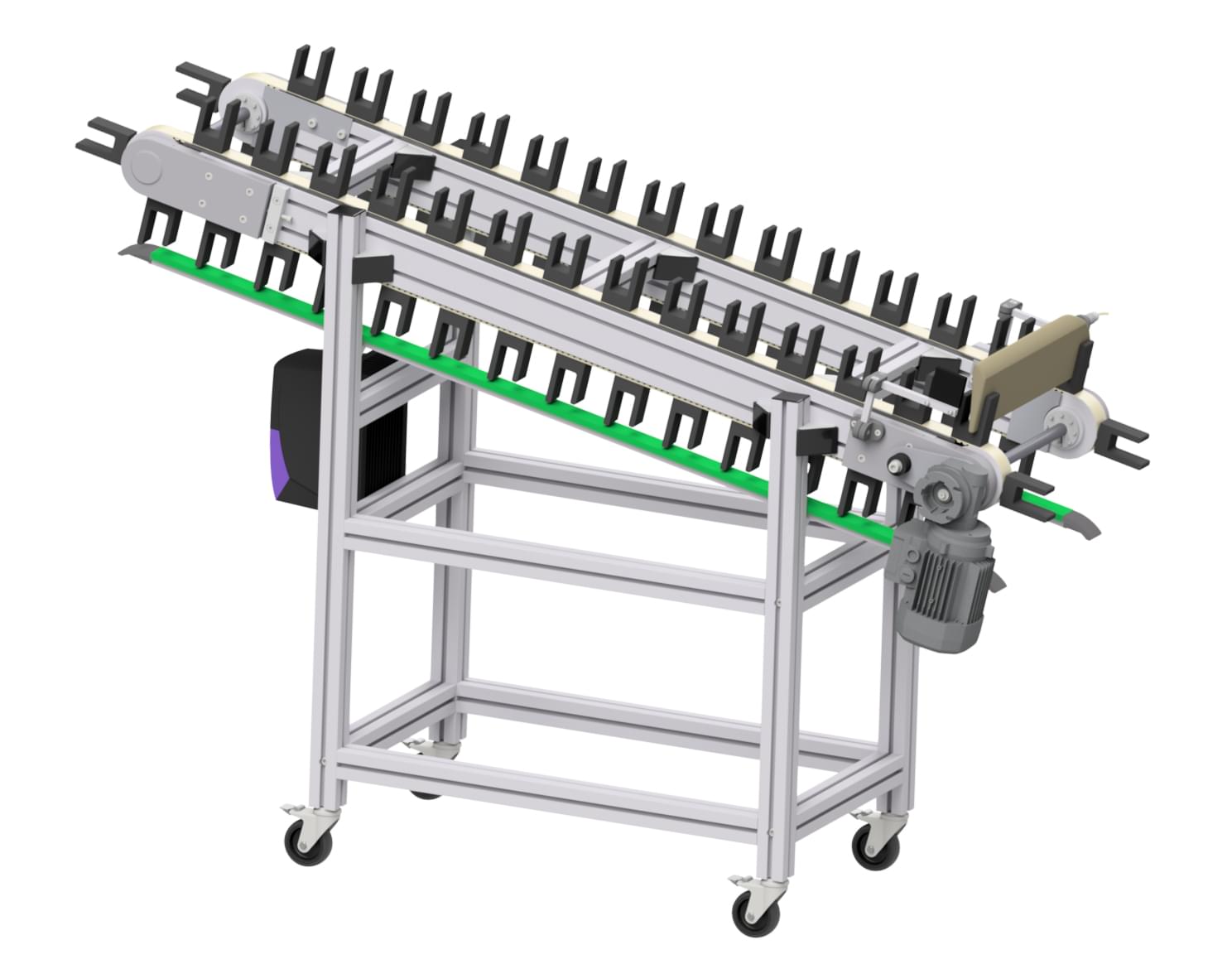

Conveyor with prefabricated fixtures

- for operations directly on the conveyor

- the belt has milled teeth in regular spacing and metal teeth with threads are placed in place of the original ones, then the jig can be mounted through the holes made in the belt into the metal teeth

- the positioning accuracy of +/-0.8 mm is influenced by the tooth module and the conveyor motion control (conveyor end sensors). In case of using a servo motor, the accuracy can be increased

Conveyor with adjustable branch

for conveying material of different widths - possibility to change the width of the conveyor

Basic parameters

| Maximum length * | 6 000 mm |

| Maximum width * | 1 500 mm |

| Hmaximum conveyor load | 100 kg |

| speed * | 3 – 80 m/min |

* the marked parameter can be increased according to the assessment of all values of the assignment

Catalogue of profiles

and accessories

On-line tools to simplify and efficiently work

with our structural aluminium system.

Expert

consultation

Our professional technical and sales representatives

will gladly answer all your questions.