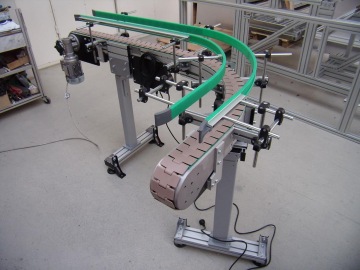

Plate apron

conveyors

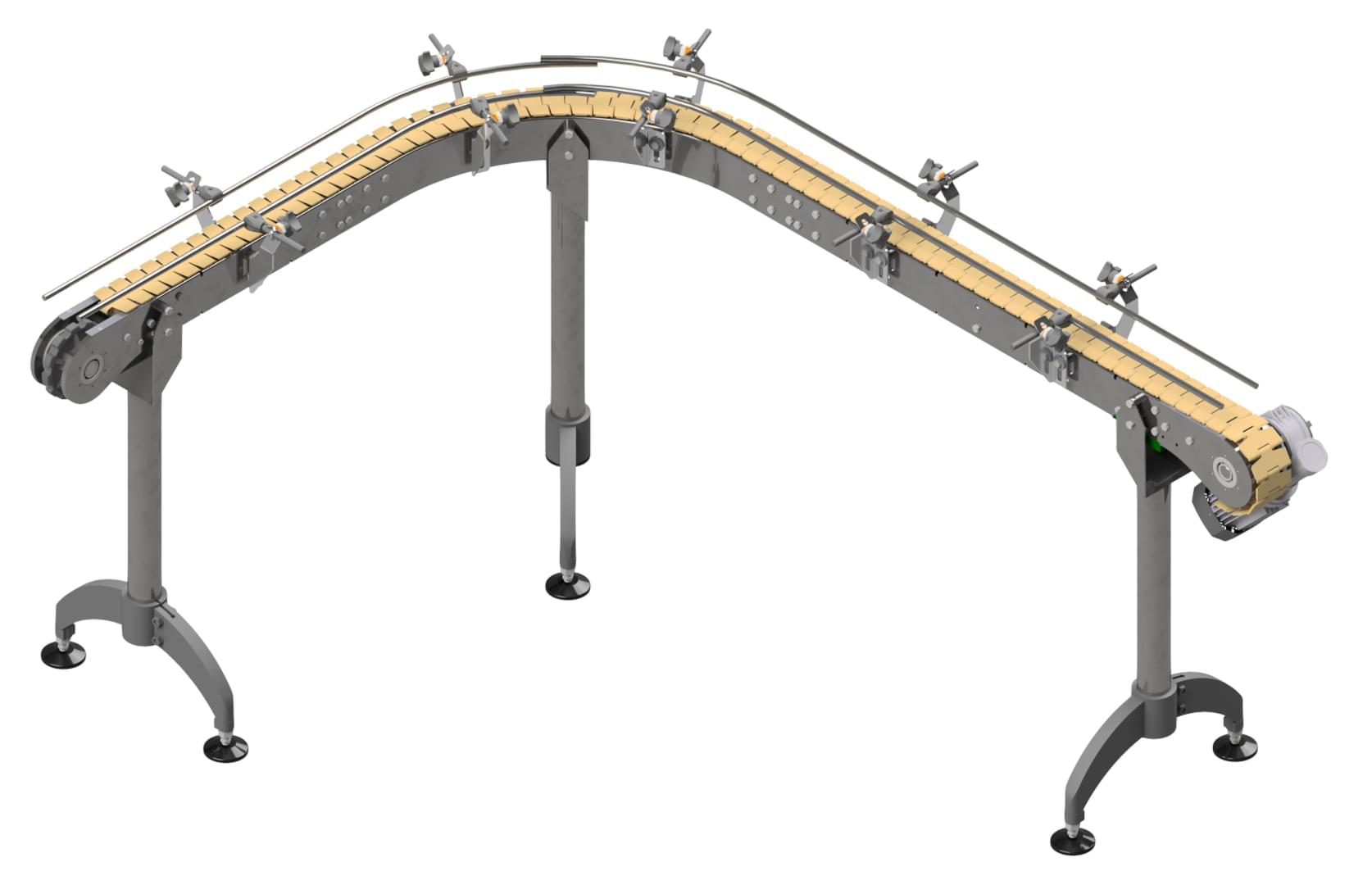

For transporting products on complex tracks using shaped sections, such as horizontal or vertical curves and bends.

The plate conveyors are suitable for a minimized built-up area and where increased resistance of the belt to mechanical damage is required while maintaining the simplicity of the elements with minimal maintenance. Available in two variants. From an aluminum construction system or from stainless steel parts and materials intended for the food and pharmaceutical industry. Also available in a variant that meets the hygienic design of EHEDG.

Properties

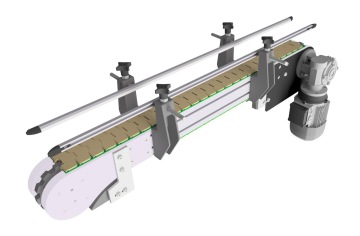

- conveyor frame, including the base made of structural aluminium system ALUTEC KK

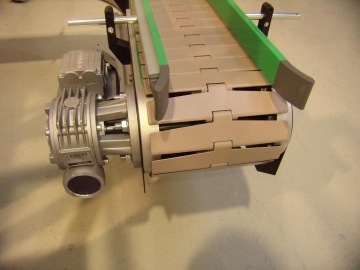

- plastic slide guideway in the top and bottom branch to support the members and reduce friction

- the driving and driven plastic gear wheels (optional steel), tensioning members

- for directions: horizontal, vertical, oblique, steep and angled

- design with horizontal or vertical radii

- fixed and mobile (travel) designs

- design of the conveyors maximally facilitates maintenance and cleaning of the installation

- modular design allows for quick replacement of components, the conveyors can be arranged both one behind another or next to each other

Drives

- electric motors and a worm bevel-helical gears, sliding mounting on driving drum shaft

- operation of conveyors can be supplemented by frequency converter, control unit and sensors for automatic control systems

Accessories

- lateral ways with vertical and horizontal adjustment

- electric adjustable columns for adjusting the height of the conveyor

- transition pieces for arranging conveyors in lines

- turn wheels

stainless steel system feature

- Frame including base made of stainless steel modular system ALUTEC KK

- Rigid and robust frame with minimal contact areas

- the conveyor legs are with fixed or adjustable feet with the possibility of anchoring to the ground, or swivel castors with a brake

- plastic sliding guide in the upper and lower branch to support the cells and reduce friction (plastic and stainless steel cells are made of material for direct contact with the product)

- drive and driven plastic gears

- for directions: horizontal, vertical, oblique, steep, angled

- versions with horizontal or vertical radii

- the construction of the conveyors maximally facilitates the maintenance and cleaning of equipment with a high drainage capacity, it is possible to install foam cleaning and then rinsing with a water shower

- detergents can be used for cleaning and sanitation to remove grease or other biological material

- the materials used are certified for direct contact with unpackaged food

- modular solution allows quick replacement of components, conveyors can be assembled behind each other and next to each other

- Also available in a variant that meets the hygienic design of EHEDG.

Drives

- aseptic electric motors and worm bevel gearboxes, sliding bearing on the drive drum shaft

- Conveyors can be controlled by a frequency converter, control unit and sensors for automatic control systems

Accessories

- side guide with vertical and horizontal adjustment

- transition parts for shifting conveyors into lines

- turn wheels

Basic parameters

Apron belts

1 250 N

steel - plastic / steel - stainless steel

63 - 82,5 – 114,3 – 190,5 – 254 – 304,8

5 – 50 m/min

Catalogue of profiles

and accessories

On-line tools to simplify and efficiently work

with our structural aluminium system.

Expert

consultation

Our professional technical and sales representatives

will gladly answer all your questions.