Accumulating chain

conveyors

Power and performance for installation into larger transport units, production and assembly lines.

Chain conveyors are designed for transport of single items larger in size and heavier in weight. An important element of the chain conveyor is an accumulation chain, version 3/8 "and 3/4" with steel or plastic wear- and oil-resistant followers. Our chain conveyors are characterised by high durability and high performance, and enable transport of very wide or long materials.

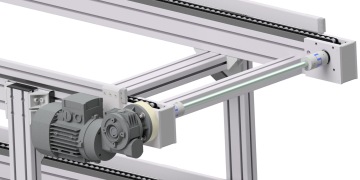

Design I

- the support frame and the base of the conveyor are made of structural aluminium system ALUTEC KK

- driving and driven steel gear wheel

- aluminium holders of driving and driven gear wheel with tilting ball bearings and a simple system for adjusting and tensing of transport chain

- drive consists of a compact unit consisting of a three-phase asynchronous electric motor and a worm transmission

- bevel-helical transmission for larger loads

- accumulation follower chains, version 3/8 “ or 3/4" with steel or plastic wear- and oil-resistant follower

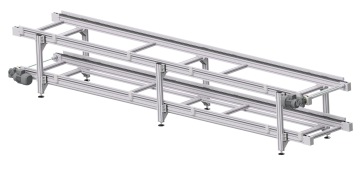

Design II

- plastic slide way under the top and bottom branch of the chain to support the entire surface of it and reduce friction

- return chain branch runs in a cavity of an aluminium profile

- speed is constant, or optionally can be adjusted with the use of a frequency converter

- possibility of vertically adjustable version manually or propelled, or an angled variant

- we deliver including electrical wiring to the motor starter or a frequency converter speed changer

Special designs

No base conveyor

for installation in your machine

Conveyor with base, ramp and lighting

for the operations taking place directly on the conveyor

Conveyor with an adjustable branch

to transport single items of different width

Conveyor with a special chain

we supply chain according to your requirements, e.g. with catch drivers

Advantages of the system

Properties

- we make conveyors to your needs

- high loading capacity

- possibility of conveying very large or long materials

- quick delivery and installation of conveyors

- you can carry out specific technology or manufacturing operations directly on the conveyor

- selectable number of branches depending on the nature of the material being conveyed

- possibility of replacing individual chain links instead of replacing the whole chain

- me make conveyor structure of ALUTEC KK profiles that are easy to connect to other profiles or complementary technologies

- the chains are designed for storage operations

Optional accessories

- wiring of the conveyors

- optical sensors with reflectors, STOP emergency buttons

- frequency converter, motor starter

- base, drive to your specifications

- plastic slide way with raised edges

- lateral guideway adjustable only in horizontal or horizontal and vertical direction

Basic parameters

Chain conveyor kit No. 930001 3/8“

minimum length

350 mm incl. heads (head length 130 mm)

maximum length

12 000 mm

maximum width

1 500 mm

maximum load

300 kg/pallet

load of the entire track

max. 1000 kg

velocity

3 - 30 m/min

Chain conveyor kit No. 930002 3/4“

minimum length

636 mm incl. heads (head length 273 mm)

maximum length

16 000 mm

maximum width

1 500 mm

maximum load

500 kg/pallet

load of the entire track

max. 1000 kg

velocity

3 - 30 m/min

Catalogue of profiles

and accessories

On-line tools to simplify and efficiently work

with our structural aluminium system.

Expert

consultation

Our professional technical and sales representatives

will gladly answer all your questions.