Pallet

conveyor system

The ideal solution for the implementation of manufacturing and assembly lines containing either automatically or manually performed operations.

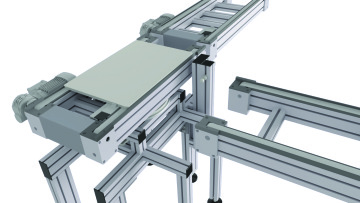

The pallet conveyor system is designed for interoperable transport of single items with a requirement of serial repeatability. The modularity of the transport system allows the assembly and adjustment of a broad range of variants of individual production requirements. The components used are robust, long lasting and enable reuse. The base of the transport system consists of a supporting frame made of aluminium profiles, a transport medium and little palettes. The selection of a suitable type of transport system is determined by the final product depending on the design of the palette and the maximum load.

Function description

The conveyor system route transports the palette from one assembly station to another. Part to be assembled is carried on the palette (carrier) on two parallel moving belts by means of friction. In the individual process steps, the palette with a part to be assembled is stopped with high precision (automatically by indexing stations or pneumatically by a stopper), while the transport system continues to move (the belts slip below the palette). The pallets do not have a position bound between them (they move independently), which enables creating of intermediate stock between the stations. Once the technological step is completed, the palette releases and continues in the track to the next technological step. At the end of the assembly process, the product is removed from the palette and the palette goes back to the beginning of the track.

Advantages of the system

- before each technological operation a queue of several palettes can be lined up, which forms a buffer stock to cover the unevenness of the process cycle

- the operator is not forced to adhere to a fixed machine cycle

- easy to change the shape of the assembly line, or include a new work cell in the existing line

- using existing parts of the conveyor system during changeover to a new production

- through exchanging the carrier, there is a possibility to assemble products of similar type on a single line, or branch the technology flow

- each pallet may store data on individual technological operations in its own memory

- based on that information, defective pieces can be rejected returned after the rework

- each conveyor system station can be gradually expanded by dedicated installations which will result in fully automatic production

Basic elements

of the Pallet transport system

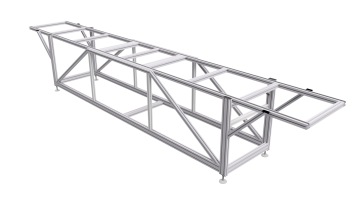

Support frame

Comprises a robust structure of ALUTEC KK structural aluminium system. It is provided with a base surface with adjusting feet to level uneven surfaces, and with anchoring elements.

Conveyor system

Individually linked conveyor sections with self-propelled pallet transport. The conveyor section is composed of a drive, a driving and a driven unit connected through a flat conveyor belt.

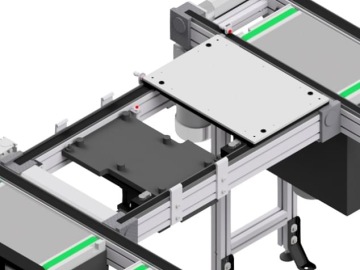

Shiftable station

Independent conveyor module located at the beginning and end of the transport branch, that serves to move the palette to and from the lateral connecting conveyor branch of the system.

Stopper

Pneumatic spacer. Is applied before the assembly technology step, prevents accidental approaching of one or more palettes to the area reserved for technology step.

Indexing station

Pneumatic unit fixing the pallet in the exact position for performing a technology step.

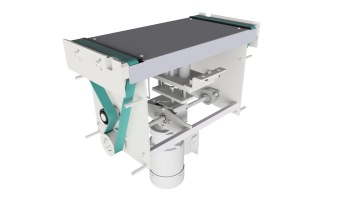

Lifting/rotary unit

Serves lifting and turning the palette in straight sections of the track.

]

Rotatable in the corner of the line

Serves rotating the palette in the corners of the line as a substitution for the shiftable station.

Hoisting unit (lift)

Is used to move the palette to different height levels of the PTS system.

Catalogue of profiles

and accessories

On-line tools to simplify and efficiently work

with our structural aluminium system.

Expert

consultation

Our professional technical and sales representatives

will gladly answer all your questions.